In the food packaging industry, efficiency, hygiene, and product preservation are key priorities. As businesses look for ways to enhance packaging operations, shrink wrap machines have become an essential investment. These machines offer a reliable solution for sealing food products, ensuring freshness, and improving overall presentation. Whether you run a small bakery or a large-scale food production facility, integrating shrink wrap technology can significantly enhance your packaging line.

This article explores the top benefits of using shrink wrap machines in food packaging and highlights how they can streamline operations while maintaining high-quality standards.

1. Enhances Food Safety and Hygiene

Food safety is a top priority in packaging, and shrink wrapping provides a protective barrier against contaminants such as dust, bacteria, and moisture. By tightly sealing food products, shrink wrap prevents exposure to harmful elements, reducing the risk of contamination.

Additionally, shrink wrap materials are often food-grade and meet regulatory standards, ensuring compliance with health and safety guidelines. This makes shrink wrapping a preferred choice for packaging fresh produce, dairy products, meat, and baked goods.

2. Prolongs Shelf Life

Shrink wrapping helps extend the shelf life of perishable food items by minimizing exposure to air and moisture. This is particularly beneficial for products such as cheese, fresh fruits, and ready-to-eat meals, which require protection from environmental factors that cause spoilage.

By using a shrink wrap machine, businesses can maintain product freshness and reduce food waste, ultimately increasing profitability and customer satisfaction.

3. Improves Product Presentation and Branding

A well-packaged product not only protects the food but also enhances its visual appeal. Shrink wrapping creates a clean, professional look by tightly wrapping items in transparent plastic, making them more attractive to consumers.

Many businesses also use shrink wrapping to incorporate branding elements such as printed labels, logos, and promotional messages. This helps create a strong brand presence and makes products stand out on store shelves.

4. Boosts Efficiency with Automation

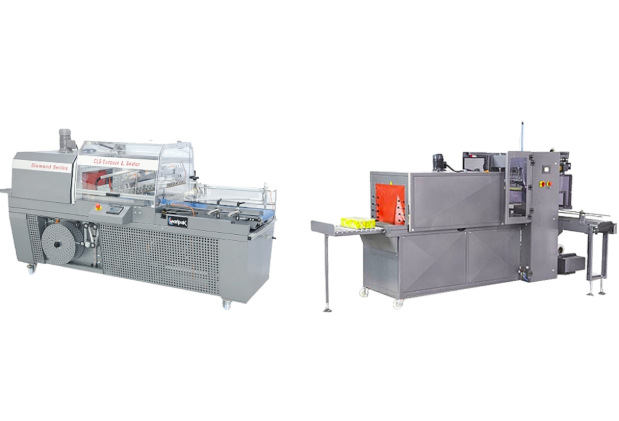

Manually wrapping food items can be time-consuming and inefficient, especially for businesses handling large volumes of products. Investing in automated packaging solutions, such as a semi automatic L sealer machine, significantly improves efficiency.

How a Semi Automatic L Sealer Machine Helps

A semi automatic L sealer machine streamlines the wrapping process by automatically cutting and sealing film around the product. This reduces manual labor, speeds up packaging operations, and ensures consistent sealing quality. It is an ideal solution for medium to high-volume food production facilities looking to enhance productivity without fully switching to an expensive automated system.

5. Reduces Packaging Costs

Shrink wrapping is a cost-effective packaging solution compared to other methods such as cardboard boxes or vacuum sealing. The materials used for shrink wrapping, such as polyolefin or PVC films, are generally more affordable, reducing overall packaging expenses.

Additionally, shrink wrap machines minimize material waste by precisely cutting the required amount of film, leading to lower costs over time. This makes shrink wrapping a budget-friendly option for food businesses of all sizes.

6. Space-Saving and Lightweight Packaging

Unlike bulky packaging materials, shrink wrap is lightweight and takes up minimal space. This is particularly beneficial for food manufacturers and distributors who need to optimize storage and transportation efficiency.

Shrink-wrapped products can be stacked easily, maximizing shelf space in retail stores and storage areas. The reduced weight also lowers shipping costs, making it a practical choice for businesses engaged in large-scale food distribution.

7. Environmentally Friendly Packaging Option

With growing concerns about sustainability, businesses are looking for eco-friendly packaging alternatives. Many shrink wrap films available today are recyclable and biodegradable, making them a more sustainable option than traditional plastic packaging.

Additionally, shrink wrapping reduces the need for excessive packaging materials, such as cardboard and foam inserts, leading to less environmental waste. By choosing eco-friendly shrink wrap films, businesses can contribute to sustainability efforts while meeting consumer demand for greener packaging solutions.

8. Versatile Application for Various Food Products

Shrink wrap machines are highly versatile and can be used to package a wide range of food items, including:

- Fresh produce (fruits, vegetables)

- Baked goods (bread, pastries, cookies)

- Meat and seafood

- Dairy products (cheese, yogurt)

- Ready-to-eat meals and frozen foods

The ability to package different food products efficiently makes shrink wrapping an excellent choice for various food industry sectors, from local bakeries to large-scale food processing plants.

Conclusion

Integrating shrink wrap machines into your food packaging line offers numerous benefits, from improving food safety and extending shelf life to reducing costs and enhancing product presentation. Whether you’re looking for a compact solution for a small food business or an advanced system for large-scale production, shrink wrapping technology provides a practical and cost-effective packaging solution.

By investing in modern shrink wrapping equipment, such as a semi automatic L sealer machine, businesses can streamline their packaging process, improve efficiency, and maintain high-quality standards in food packaging. In an industry where presentation, freshness, and safety matter, shrink wrap machines offer a game-changing advantage for food packaging operations.