The industrial environment often depends on the right tools. If your operators are provided with the right tool, they might find it easy to manage their work in the given timeline. The tools such as nut bolt tightening machine and torque wrenches are two of the most used tools in the industry and they should be precise and up to the mark for the positive outcomes and less workload on the operators.

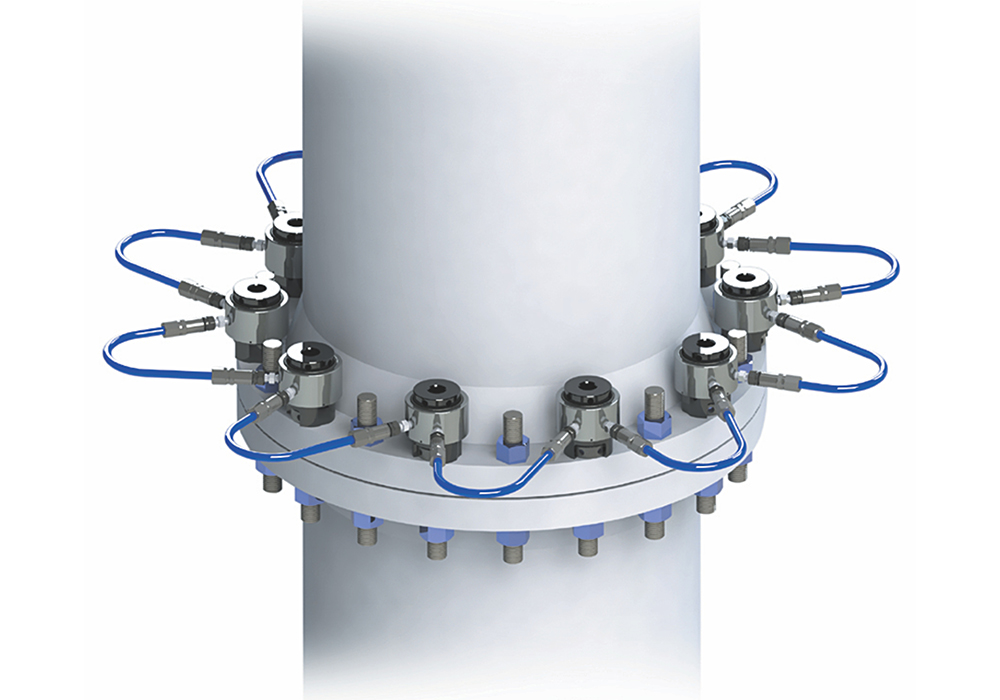

Oil rings and power plants need advanced tools that provide safety, speed, and are extremely precise. These tools are designed to replace the manual effort with the automated high-torque solutions. These machines ensure that the fasteners are tightened according to the specifications without any chances of errors and structural failure.

The Role of Precision in Heavy Machinery

To manage the heavy machines in the manufacturing industry, the selection of the right tool is very crucial. Hence, one should first understand the need of your heavy machine and find the tools accordingly. For bolted joints to resist vibration, thermal expansion, and mechanical stress, they must function similarly to springs and maintain a certain clamp load.

- Modern equipment allows easy bolt stretching without causing harmful torsional stress.

- The use of torque wrenches allow your operators to deal with the overtighting with the automated stop button.

- In high-pressure pipelines and heat exchangers, it is essential to maintain consistent tension across all fasteners to avoid gasket crushing or leaks.

Enhancing Efficiency on the Production Floor

In the industry efficiency is a must. The use of torque wrenches could enhance the efficiency of the production floor. A switch from manual wrenches to the advanced one must be considered as it allows:

- Reduced operational time

- Automation feasibility

- Easy to handle and use

- Prolonged operations

Safety and Ergonomics for Operators

Heavy assembly often involves massive bolts that require thousands of foot-pounds of torque. This could be dangerous, hence, the use of the torque wrenches will be more safe for operators.

- Reduced physical strain for operators in the industry.

- In dangerous areas like offshore rigs or subsea installations, it is essential that operators stand at a safe distance while the tensioning process is taking place. This can be done by tightening devices safely and precisely.

- The jarring impact that traditional impact tools frequently produce is eliminated by automated equipment, which deliver smooth, controlled power.

Technological Innovations in Tightening Equipment

The evolution of bolting technology has introduced various specialized tools that streamline different phases of the heavy assembly line.

- Hydraulic bolt tensioners.

- Pneumatic and electric torque wrenches

- Torque multipliers, essential for fieldwork and maintenance

- Digital Data Logging

Conclusion

The use of these tools guarantee the safety of the operators across the industry. Manufacturers could get the desired outcome and quality in their products while using automated tools that allow operators to work without a workforce. The production flow will be on the track with the use of premium quality torque wrenches and a nut bolt tightening machine.

Providers are launching new tools that offer precise detailing and more safety with the quick operational features for industrial use.